The Main Principles Of Harvest Right Freeze Dryer

Table of ContentsNot known Incorrect Statements About Harvest Right Freeze Dryer Harvest Right Freeze Dryer Fundamentals ExplainedThe 45-Second Trick For Harvest Right Freeze DryerFascination About Harvest Right Freeze DryerHarvest Right Freeze Dryer for BeginnersThe Best Guide To Harvest Right Freeze Dryer

There are 3 stages in the lyophilization procedure: Pre-freezing, main drying out, and also secondary drying. The pre-freezing stage is the most essential stage of the freeze-drying process.The rate at which your example ices up will certainly influence the size of the ice crystals that create. Otherwise done correctly, it can affect the speed of reconstitution, size of the freeze-drying process and integrity and also stability of your sample. Larger ice crystals assist in faster as well as much more efficient lyophilization since water particles have the ability to move extra freely out of the example during sublimation.

Our Harvest Right Freeze Dryer Ideas

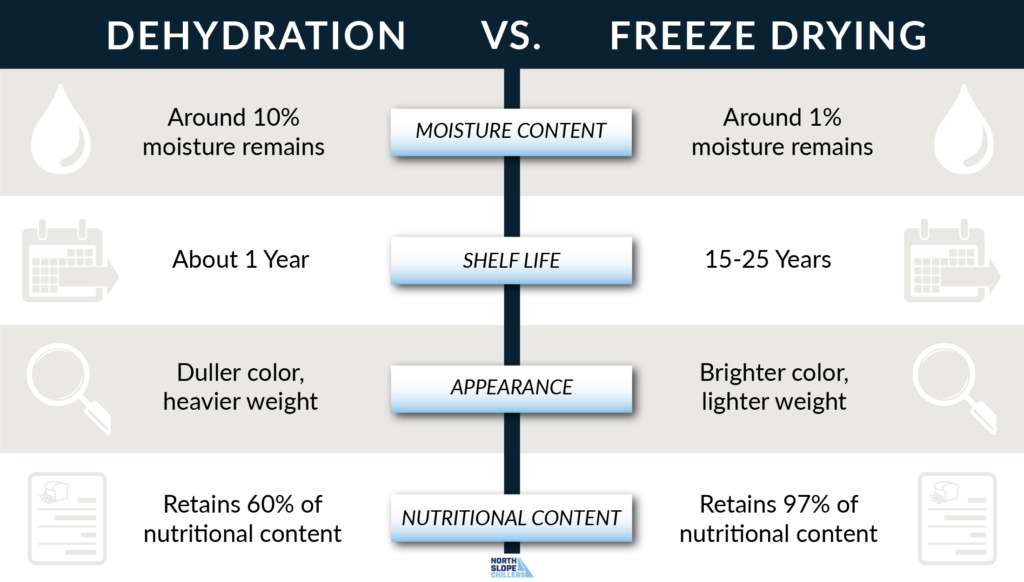

Additional warm is included in this phase to drive off excess moisture, leaving behind a wetness material of about 2%. Additional drying out is usually utilized in examples that are being prepared for lengthy term preservation and storage. While freeze drying can accomplish many points, its key goal is to safeguard the biological and also chemical structure of a sample through the process of sublimation.

In the research laboratory, the applications of freeze drying are endless.

The 4-Minute Rule for Harvest Right Freeze Dryer

Freeze drying out is simplest to accomplish using huge ice crystals, which can be produced by slow freezing or annealing. With biological products, when crystals are also huge they might damage the cell wall surfaces, as well as that leads to less-than-ideal freeze drying results.

About 95% of the water in the product is removed in this phase. Key drying out can be a sluggish process. Way too much warm can modify the framework of the product. Freeze drying out's final phase is second drying out (adsorption), throughout which the ionically-bound water molecules are removed. By increasing the temperature more than in the key drying stage, the bonds are broken in between the material and the water molecules.

9 Easy Facts About Harvest Right Freeze Dryer Explained

After the freeze drying out procedure is full, the vacuum can be damaged with an inert gas before the product is secured. The majority of look at this web-site products can be dried out to 1-5% residual wetness.

Freeze-drying or lyophilization is a dehydration method based upon the sublimation of water in a product (, ). This indicates that the product's water web content shifts from a solid to an aeriform state or from ice to vapor without undergoing the liquid state (). Freeze-drying is thought about a top quality dehydration approach for a number of factors, consisting of (, ): it operates at reduced temperatures, which adds to maintaining a product's dietary value, preference, look, as well as heat-sensitive compoundsfreezing prevents chemical as well as microbiological processes, which dramatically delays the product's wear and tear (consequently expanding its shelf life) Raw foods are included about 80%95% water, which can be separated into "free" and "bound" water.

In the freeze-drying procedure, all free water and also some bound water should be removed, as well as cost-free water must stay frozen in all times. This is the main distinction between freeze- as well as vacuum-drying and also the most challenging step (). The freeze-drying process can be divided right into 3 actions (,, ): The product is commonly iced up under air pressure.

How Harvest Right Freeze Dryer can Save You Time, Stress, and Money.

Additionally referred to as desorption drying out, it's the drying out of products to their wanted moisture by removing the staying bound webpage water. Freeze-drying must be done in controlled problems that do not thaw the water, seeing that the presence of liquid water might alter the item's make-up, shape, and physical residential properties ().

The basic principle in suspended animation is sublimation, the shift from a strong directly right into a gas. Similar to dissipation, sublimation happens when a particle image source gains sufficient energy to break devoid of the particles around it. Water will superb from a strong (ice) to a gas (vapor) when the molecules have sufficient power to damage complimentary but the conditions aren't right for a liquid to develop. Harvest Right freeze dryer.

For a material to take any specific stage, the temperature level as well as pressure should be within a certain variety. Without these problems, that phase of the material can not exist. The chart listed below programs the needed pressure and temperature worths of various phases of water. You can see from the graph that water can take a liquid kind at water level (where pressure amounts to 1 atm) if the temperature level remains in between the water level freezing point (32 degrees Fahrenheit or 0 degrees Celsius) and the sea level boiling point (212 F or 100 C).

The Basic Principles Of Harvest Right Freeze Dryer

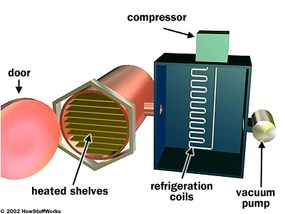

06 environments (ATM), the water is cozy sufficient to thaw, yet there isn't adequate pressure for a fluid to develop. It ends up being a gas. This is precisely what a freeze-drying machine does. A regular equipment includes a freeze-drying chamber with numerous racks connected to heating devices, a freezing coil attached to a refrigerator compressor, and an air pump.